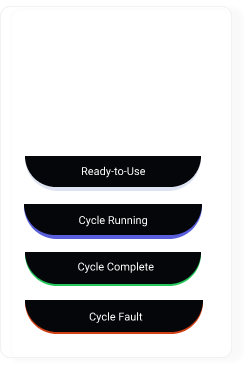

Intuitive Interface

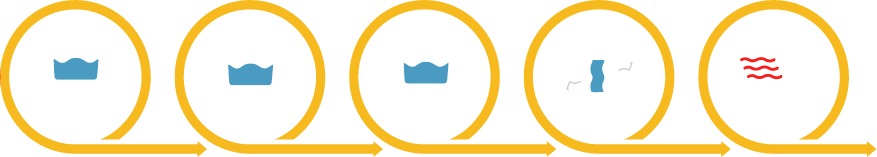

+ Cycle information graphic shows each phase.

+ On-screen tutorials to help on-board new staff.

+ Pop-up troubleshooting tips for easy corrective actions.

Your Submission has been received

The stericentre is the most labour-intensive room in the dental office. Dental assistants, on average, enter the stericentre over 80 times a day. HYDRIM’s automated, validated cycles take care of pre-rinse, washing and drying to give your team more time for patient care.

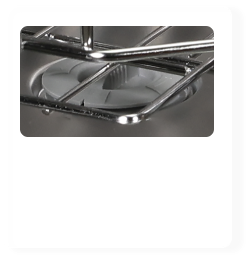

If your team is hand scrubbing instruments, they’re increasing their chance of injury. As many as 31% of sharps injuries occur during instrument reprocessing, specifically during the cleaning step.* HYDRIM washes, rinses and dries using a fully automated process that can virtually eliminate individual instrument handling when used in combination with cassettes.

Variability is no way to start an instrument cleaning process. But for offices where the first step is manual or ultrasonic cleaning, results can vary from insufficient cleaning to instruments that are not fully dried. HYDRIM’s intelligent systems make washing a validated and repeatable process. Your instruments are cleaned and dried to the same standard, every time.

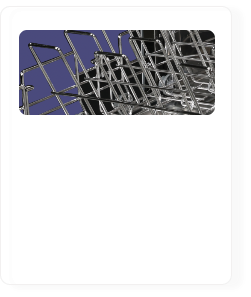

Hand scrubbing instruments takes longer, cleans fewer instruments at a time and can lead to errors and missed steps. As a safe and efficient part of a high functioning workflow, HYDRIM’s large chamber handles up to 250 instruments per cycle making it ideal for use in offices with up to 10 operatories.

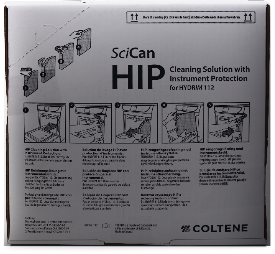

From its reconfigured wash chamber and intuitive touchscreen to its integrated detergent system and LED cycle status indicator, our newest HYDRIM is designed to improve your workflow – and your bottom line.

+ Cycle information graphic shows each phase.

+ On-screen tutorials to help on-board new staff.

+ Pop-up troubleshooting tips for easy corrective actions.

+ A connected HYDRIM can enable remote monitoring, troubleshooting and diagnostics.

+ Maintenance reminders keep your unit performing optimally.

+ Connected units receive automatic software updates for all the latest features.

+ Every cleaning cycle is logged and maintained over the full life of the unit.

+ Redundancy in data storage provided via both unit and USB.

+ Connectivity to myCOLTENE provides additional redundancy in cycle storage and traceability.

READY FOR

STERILIZATION

READY FOR

STERILIZATION

READY FOR

STERILIZATION

Fill out the form to let a SciCan product Expert contact you.